-

Notifications

You must be signed in to change notification settings - Fork 151

Manual Soldering

Often the nRF module is unavailable for assembly at JLCPCB. You may purchase the module separately and solder it by hand.

I use a cotton swab and isopropyl alcohol (IPA) both on the PCB's and on the module's pads.

This is by far the most crucial step. To align the module with the footprint, I start with a small solder blob on a single pad:

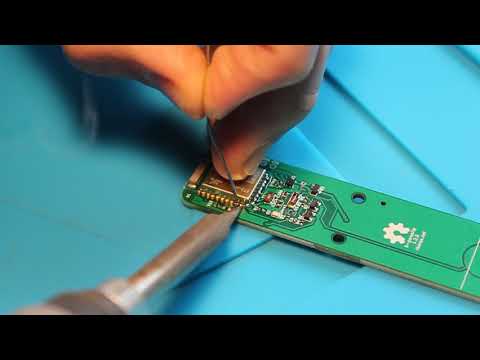

Then I place the module and temporarily set it in place (video):

I do the fine alignment by melting the single solder joint and gently moving the module around until the all the pads on all three sides are aligned. I take my time and repeat this as many times as needed, until the alignment is as good as possible:

Important: Be careful not to twist or lift the module when its being held by this single joint - any small force will rip out the pad from the PCB. That's why I use a non-connected pad for this step. If I accidentally ruin it, there's still hope. It hasn't happened so far.

I apply flux and briefly place the soldering iron + a tiny bit of solder on each pad, one side at a time (video):

I find that less is more. I use just a tiny bit of solder for each pad.

I again use a cotton swab and isopropyl alcohol to get rid of the flux.

After cleaning up the flux, I can spot two of the most common defects on each solder joint:

- Gap between the module and the PCB pads. Likely happens if the pad is not heated up enough while soldering, so all the solder only sticks to the module. Placing the soldering iron (without extra solder) again for 1-2 seconds normally solves the issue

- Bridges between two pads. If there's too much solder, I go in with a wick wire and get rid of it. Most of the time just reflowing the solder with the soldering iron is already enough to fix it

Steps 1 and 2 are the same as for Method 1. Clean and align with a single solder joint.

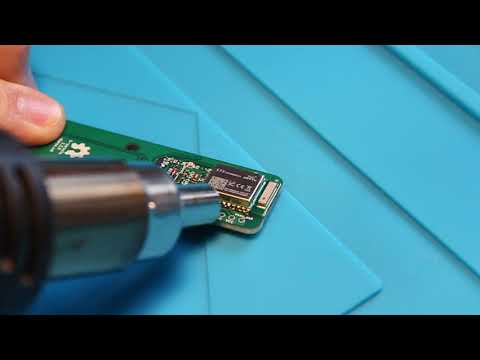

It's usual to apply the solder paste before placing the component that's being soldered, but since alignment is so important, I apply the solder paste after aligning, on top of the pads.

I set the hot air station to 360-400 °C and let it work its magic (video):

I then cleanup, visually inspect and rework bad joints.